Section 4 of Mechanical Behaviors and Properties of Gaskets: Tensile Strength and Blow-out Resistance.

In the gasket field, gaskets of different materials have distinctly different requirements and key focuses for tensile strength due to their inherent characteristics.

First, let us look at non-metallic gaskets. Most of such gaskets are made from rubber-bonded fiber-reinforced sheets via the conventional compression method. During the manufacturing process, fibers form a specific alignment direction, which results in inconsistent transverse and longitudinal tensile strength of the gaskets, with the transverse strength often lower than the longitudinal strength.

This characteristic makes transverse tensile strength a key indicator for judging the performance of non-metallic gaskets: insufficient transverse strength will cause gaskets to crack or tear easily when subjected to slight transverse tension during installation or transverse stress generated by pressure fluctuations during use, which in turn leads to sealing failure.

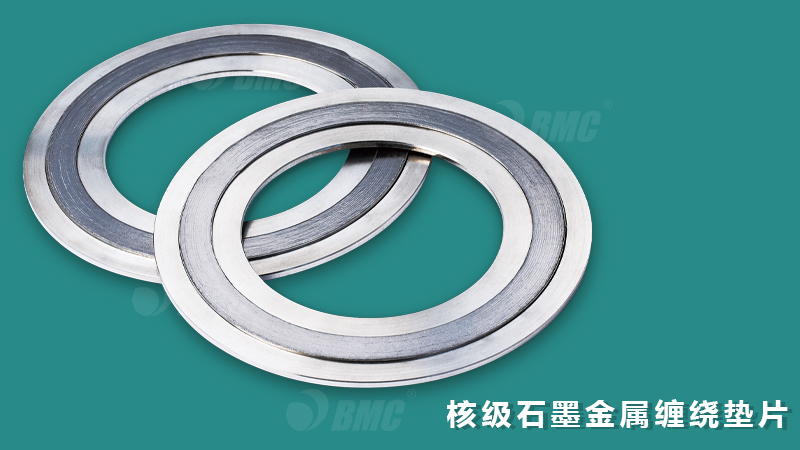

In contrast, semi-metallic gaskets and metallic gaskets have substrates with outstanding mechanical properties, and their tensile strength is far higher than that of non-metallic sheets. Therefore, tensile strength is no longer a key factor to be considered in actual selection and application.

To help everyone understand the tensile strength tests more intuitively, screenshots of relevant tests can clearly show the stress changes of gaskets during the stretching process, facilitating a quick grasp of the tensile performance characteristics of different gaskets.

Ingenious Seal Mastery

For sealing leakage issues, Baohua provides solutions. If you have any doubts about sealing technology, please pay attention to Suzhou Baohua and feel free to consult, comment, or leave a message! Thank you all! we will continue to talk about tensile strength and blow-out resistance. See you next time!

Email:marketing@mybmc.com.cn

Email:marketing@mybmc.com.cn