Mechanical Behavior Performance of Gaskets

Load-Deformation Behavior

Today, we continue to introduce the mechanical behavior properties of gaskets - load-deformation behavior.

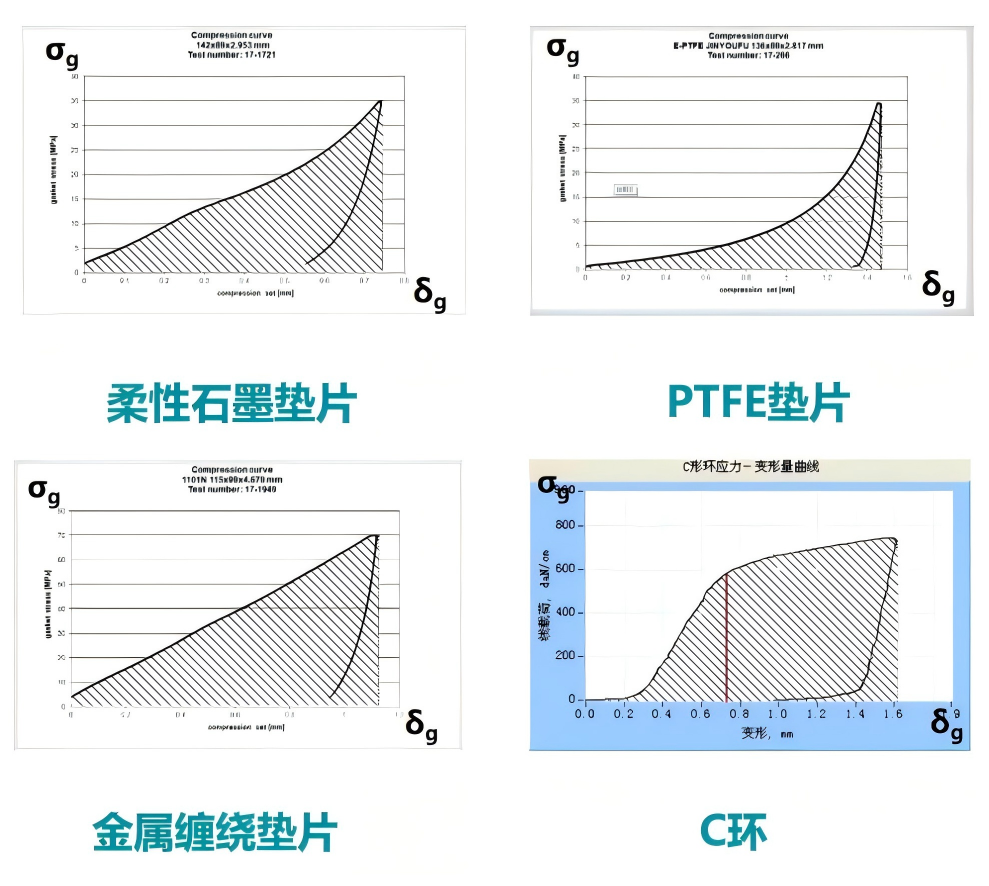

Different Corresponding Relationships between σg and δg

Different materials and types of gaskets have completely different load-deformation behaviors.

As shown in the above figure, there are significant differences in the shapes of the corresponding relationship curves between σg and δg for flexible graphite, PTFE, metal wound gaskets, metal C-rings, etc.

BMCMulgraf:Good medium resistance and wide application range

Judging from the shaded part of the curve, this area represents the work done to compress the gasket. The larger the area, the more energy is required to compress the gasket, and the gasket is relatively "harder"; the smaller the area, the "softer" the gasket.

BMC modified PTFE sheet gasket has good flexibility

For example, the shaded area of the PTFE gasket curve is small, which is much "softer" than flexible graphite and metal wound gaskets, and is easier to compress.

The curve of the metal C-ring is more unique. When the compression amount reaches a certain level, it will change from elastic deformation to plastic deformation. This means that beyond the critical point, even if part of the stress is removed, the deformation is difficult to fully recover. Only by mastering the characteristics of different gaskets can we match the actual working conditions when selecting types.

Ingenious Seal Mastery

For sealing leakage issues, Baohua provides solutions. If you have any doubts about sealing technology, please pay attention to Suzhou Baohua and feel free to consult, comment, or leave a message! Thank you all! We will continue to talk about load-deformation behavior in the next issue. See you next time!

Email:marketing@mybmc.com.cn

Email:marketing@mybmc.com.cn